Aircraft Starting Magnetos

An aircraft starting magneto is designed to be turned rapidly by hand to produce a continuous stream of sparks. The front of the magneto includes a spindle fitted with a small crank handle There would be, typically, a 5:1 gear between the armature and the spindle so that the armature turns 5 times faster than the handle.

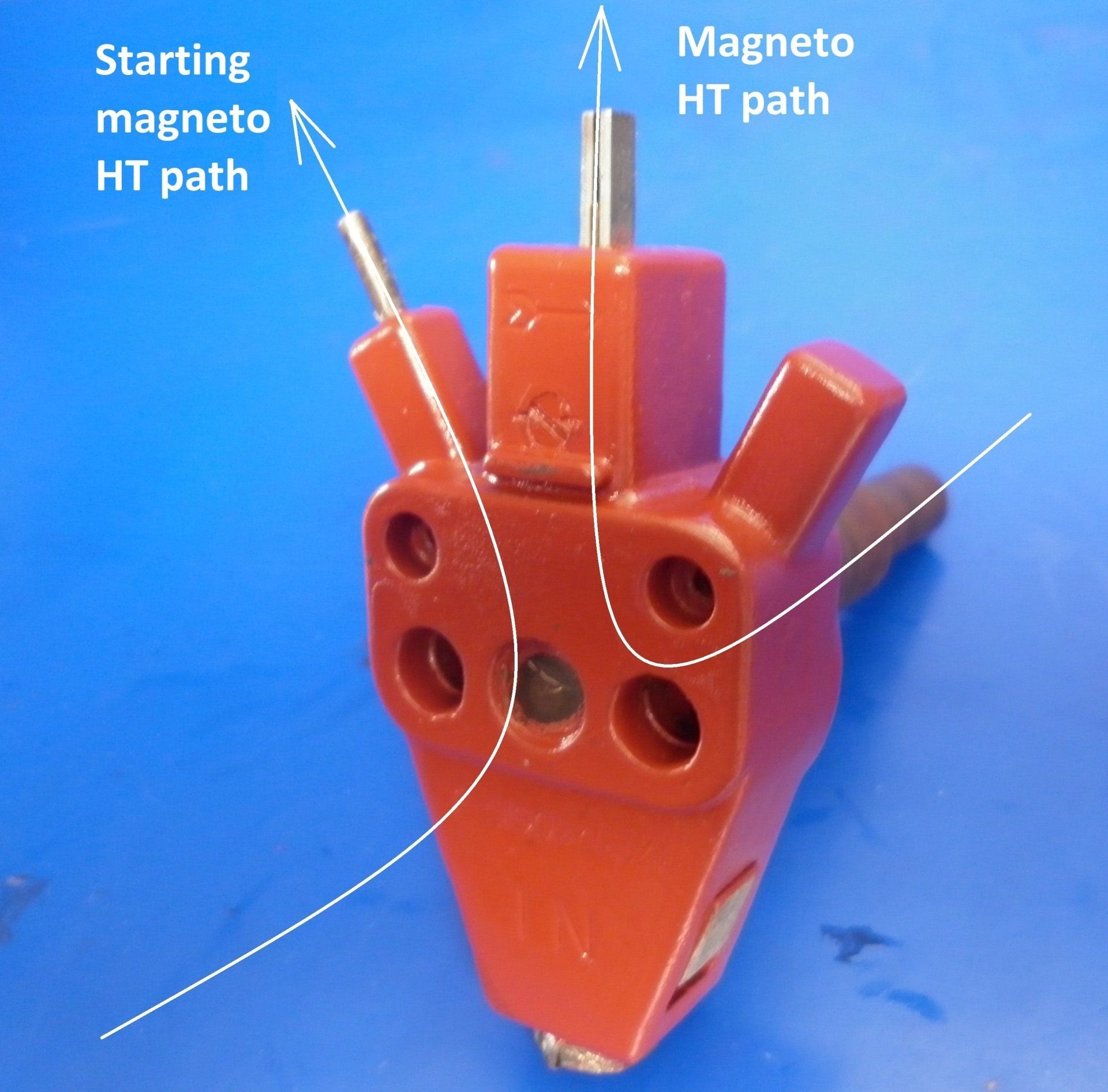

A starting magneto is needed because the mechanic trying to spin the prop, wouldn't be able to swing it fast enough to get a spark out of the main magneto. The handle on the starting mag is turned by a second mechanic and is used to feed a continuous stream of sparks to a dual magneto fitted to the aircraft engine. Once the engine starts the pilot would switch over to the normal magneto and the starting magneto is then redundant until it's time to start again. Some aircraft magnetos only have one HT output. This was fed into the starter terminal on the distributor section of the engine’s main magneto. So only one source of spark on the starting magneto but this was then distributed to however many cylinders/plugs the engine had by the main magneto's distributor. Some starting magnetos have two HT outputs. These were used on engines fitted with two main magnetos - one starting magneto output to each of the starting terminals on the two main magnetos.