Overseas sales always welcome! Please check IMPORTANT NOTES FOR OVERSEAS CUSTOMERS

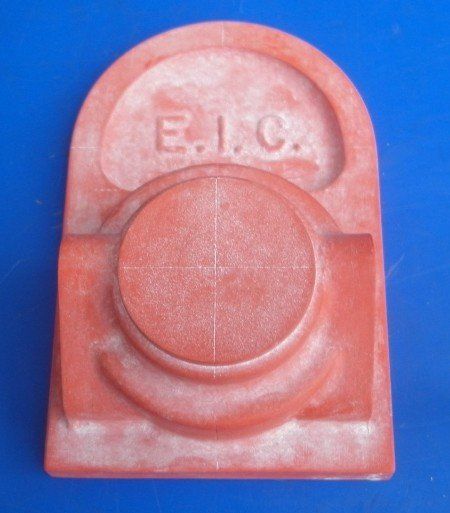

EIC Magneto Drive End Plate Casting Single Cylinder

For Overseas Sales:

ONLY £60.00 incl. P&P!

EIC Magneto Drive End Plate Casting Twin Cylinder

For Overseas Sales

ONLY £60.00 incl. P&P!

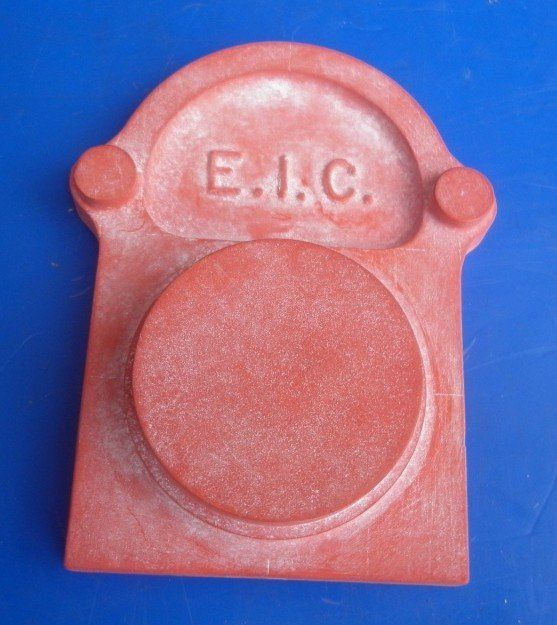

EIC Magneto Contact Breaker End Plate Casting

For Overseas Sales

ONLY £60.00 incl. P&P!

Dixie base casting

For Overseas Sales

ONLY £80.00 incl. P&P!

Round ML bearing/face cam casting

Cable on LEFT

For Overseas Sales

ONLY £47.00 incl. P&P!

SORRY - Currently out of stock

For UK Sales

ONLY £41.00 incl. P&P!

For Overseas Sales

ONLY £47.00 incl. P&P!

For UK Sales

ONLY £59.00 incl. P&P!

For Overseas Sales

ONLY £65.00 incl. P&P!

For UK Sales

ONLY £59.00 incl. P&P!

For Overseas Sales

ONLY £65.00 incl. P&P!

For UK Sales

ONLY £42.00 incl. P&P!

For Overseas Sales

ONLY £48.00 incl. P&P!

For UK Sales

ONLY £56.00 incl. P&P!

For Overseas Sales

ONLY £62.00 incl. P&P!

For UK Sales

Only £24.00 incl. P&P!

For Overseas Sales

Only £30.00 incl. P&P!

For UK Sales

Only £76.00 incl. P&P!

For Overseas Sales

Only £82.00 incl. P&P!

Overseas sales always welcome! Please check IMPORTANT NOTES FOR OVERSEAS CUSTOMERS